Products & Finishes

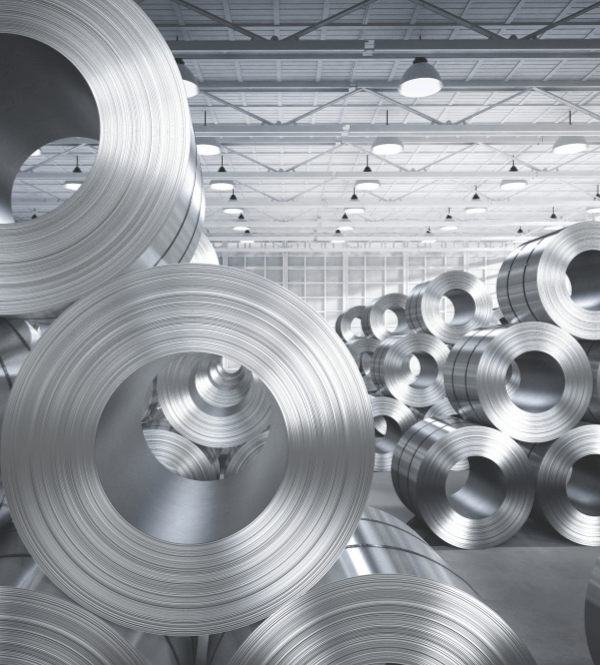

Stainless Steel Coil 200/300/400 Grade

| Thickness | 0.3 mm to 6 mm |

| Width | 32 mm to 1500 mm |

| Finish | 1D/N1 | 2B | 2E | BA | Chequered | Embossing/ Slip Free | Hair Line | Mirror/No. 8 | Scotch Bright | No. 4 |

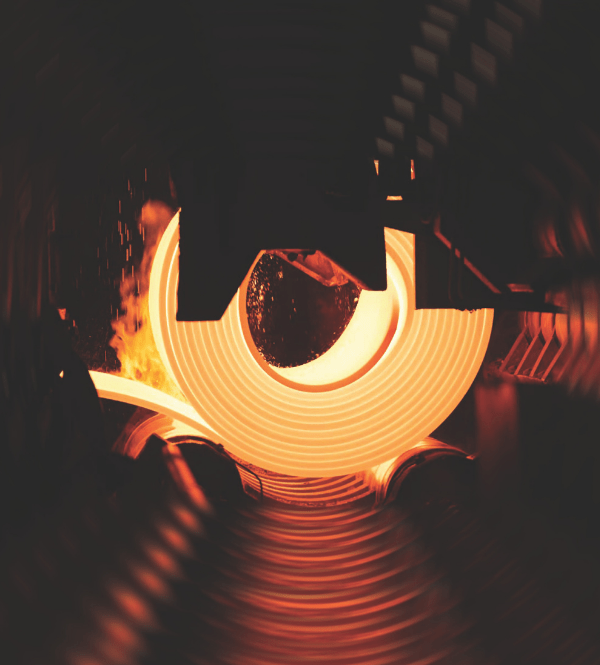

-Hot Rolled Coil

-Hot Rolled Coil

Structural components: Beams, channels, angles, and other structural elements in buildings, bridges, and other construction projects.

Automotive parts: Frames, chassis, and other components that require strength and durability but do not need a polished finish.

Machinery: Parts like gears, shafts, and housings where precise dimensions and finishes are not essential.

Forging: As a starting material for forging processes to create various shapes and components.

-Cold Rolled Coil

-Cold Rolled Coil

Automotive parts: Body panels, fenders, doors, and other components that require a high-quality finish and precise dimensions.

Appliances: Components like refrigerator panels, washing machine drums, and stove tops.

Construction: Roofing sheets, siding panels, and other architectural elements.

Machinery: Precision components like gears, shafts, and bearings that require high tolerances and finishes.

Stamping: As a starting material for stamping processes to create complex shapes and components

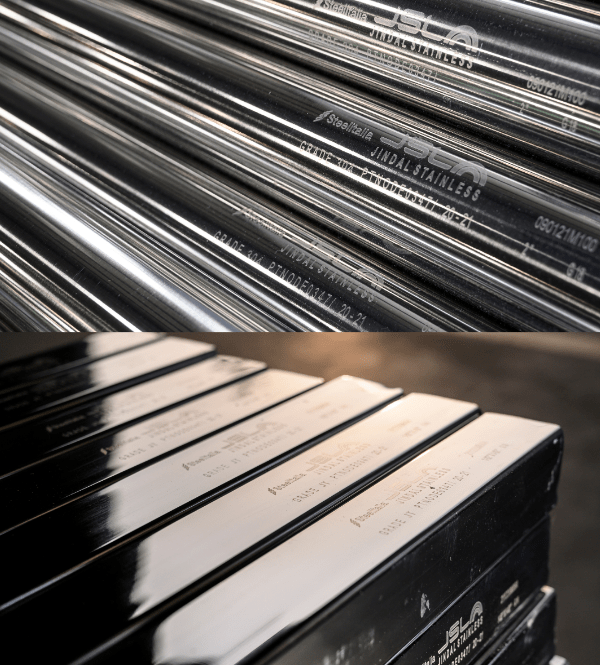

Stainless Steel Plates 200/300/400 Grade

| Thickness | 4 mm to 10 mm |

| Width | 800 mm to1650 mm |

| Length | 1000 mm -12000 mm |

| Finish | 1D/N1 |

-Applications

-Applications

Construction and Architecture: Cladding, structural components, decorative elements, elevators.

Food Processing and Hospitality: Kitchen equipment, food processing machinery, hospitality equipment.

Industrial Applications: Machinery components, chemical processing, pharmaceutical manufacturing, oil and gas industry.

Transportation: Automotive industry, marine industry, railroad industry.

Medical Equipment: Surgical instruments, hospital furniture, equipment.

Consumer Products and Others: Appliances, cookware, cutlery, art, sculpture.

Stainless Steel Pipes and Tubes 200/300/400 Grade

| Thickness | 1 mm to 3 mm |

| Outside Diameter | 12.7 mm to 101 mm |

| Length | 6100 mm |

| Finish | 2B | Mirror/No. 8 | No. 4 |

-Applications

-Applications

Structural Support: Stainless steel pipes are used as structural elements in buildings, bridges, and other infrastructure projects, providing strength and durability.

Plumbing Systems: Their corrosion resistance makes them ideal for plumbing systems, ensuring long-lasting and efficient water flow.

Architectural Features: Stainless steel pipes can be used for decorative elements like railings, handrails, and architectural accents, adding a modern and sleek touch.

Automotive: Stainless steel pipes are used in exhaust systems, fuel lines, and other components of vehicles.

Household Appliances: Stainless steel pipes are used in refrigerators, washing machines, and other appliances.